PRODUCTS OVERVIEW

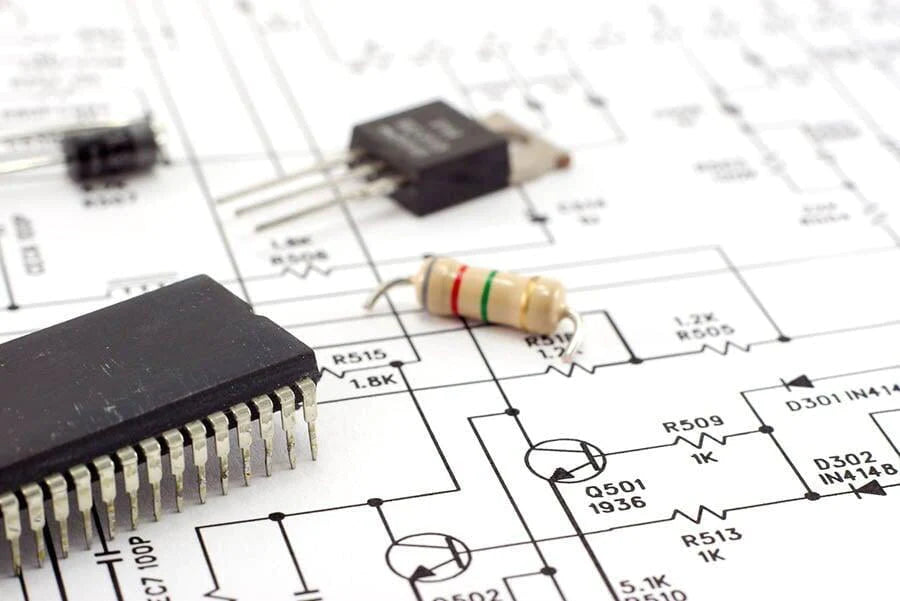

Complete Vision System Solutions

What people have said about us

Read some of our customer reviews and testimonials.

R Zakoor

Purchasing

I appreciate all your hard work. You always try to keep me informed and take extra steps to make sure we cover our butts. Not a lot of our suppliers do that for us.

D Rosenfeld

Thank you for assisting us with the lens and working under our strict deadline. The ability to get the lens so quickly was a huge help to us!

H Gilsenan

Senior Buyer

I can say with all sincerity

that the very best attention to detail from beginning to end, along with the

most personable service with a healthy touch of professionalism – has been

experienced through my dealings with Andre.

He stands out from all the other

inside sales and account manager specialists I have dealt with. He’s that good.

M Castellanos

Analyst

Maria Yrbas has been our Lore Account rep for quite some time now and we couldn’t be happier with the services she provides us. She takes the time and care into everything we ask of her.

She is thorough in everything she does and never misses any details. She goes above and beyond, especially with turnaround time for quotes…I am never left hanging. If she’s unavailable for some reason, she always lets us know who we can contact. She is our “go to” for all of our camera needs. I am truly happy she is our rep and for a while now, my friend. She is an asset!

Z. Zaidi

Working with you has been an absolute pleasure. Your dedication and commitment to ensuring that we received the right products for our project have been unmatched. You've always been responsive to our needs and have gone above and beyond to ensure that we were satisfied with your services.

I appreciate your willingness to help me with preparing quotes that were tailored to our specific needs, which made our purchasing process a breeze.

Your knowledge of the industry

and your ability to provide suggestions for the right products for our use case

have been invaluable. Your accurate lead times and timelines for products have allowed us to plan our project efficiently and effectively. Your assistance and support have helped our project progress and deliver the desired results as evidenced by our recent video.

P Sanchez

Project Coordinator

Maria Yrbas was extremely helpful in facilitating the account set up with Lore Technology and more importantly was able to work within our budget. Maria was attentive every step of the way and made it possible to meet the strict timeline with our client. We look forward to continuing working with Maria and Lore Technology.

M. Groth

Andre has been providing top notch service since we started working with your company a few months ago, he responds quickly to any email and if he doesn't have an immediate answer to my question, he keeps me in the loop as he is trying to figure it out. Andre always sends updates as lead times change and has made it very easy to continue to use your company as our lens and filter supplier. 5 stars for customer service and support.

I. Arce

Andre is a fantastic resource; he is proactive in informing me of the availability of Flir items if there is a need for them, and he gives prompt responses to inquiries, order confirmations, and tracking information. Thank you for the help, Andre, greatly appreciated!

.Bagnell

Senior Quantum Engineer

We have been extremely pleased with the services provided by Lore+/Wilco. As our primary point of contact, we have also been very pleased working with Maria Yrbas. We appreciate her responsiveness, attentiveness to detail, and assisting in the successful completion of our projects. Thank you to Maria and the whole Lore+/Wilco team for helping us to be successful.

K. Dehart

Purchasing Manager

Just wanted to reach out and say thank you Andre for the prompt response as well as the phone call to inform me.

It’s rare to find such great service nowadays. I really appreciate it!

R. Silva

I would like to thank you for all your service. You always kept me informed about every step of the purchase and always looked for the

best alternatives to serve me as quickly as possible. You and your team were always available and always quick to support and send information. Thank you for everything!

Pat H.

Mechanical Engineer

I can not speak high enough praise for Maria and the rest of her team! Her timely responses and punctuality allow our team to deliver the best research products for our customers. Maria is professional, knowledgeable, and does an excellent job at communication during the entire procurement process.

Andrew M.

Mechatronics Engineer

I have been working with Maria to buy imaging sensors and camera components. I am an engineer and I work with many different sales reps in designing our machine vision solution for agriculture. Maria has consistently been the most helpful and responsive sales rep that I have the pleasure of working with. She is able to get me the components I need on schedule. She also gives me detailed insight into the supply chain so that I can make purchasing decisions in advance.

V. Pessino

Ph.D

I appreciated all the help and efforts over these years from Maria

Yrbas, and I will absolutely keep her in mind for future work. Best

wishes~ Veronica

Steve C.

Chief Production Officer

Thank you Maria for staying after this and helping us coordinate with Basler. I wish every partner was as proactive, persistent and responsive as you’ve been! Greatly appreciated!

N Kulkarni

Dept of Materials Science

I highly appreciate the help that Maria has extended during procurement of Flir Camera and Tamron Lens. She clarified all our queries regarding performance and integration of the system.

Van Horn

Engineer

I would also like to thank you for the wonderful experience working with you! You have always had our best interest and helped so much in getting the system up and running.

E Hueners

Operations Manager

When faced with supply chain uncertainties, it is vital to have the Darlene and Lore Tech team on your side. Her prompt and knowledgeable responses have allowed us to navigate successfully through camera challenges that risked shutting down our production line. They have always worked with us to find the optimal solution to our lead time issues to keep our production running!

R Zakoor

Purchasing

I appreciate all your hard work. You always try to keep me informed and take extra steps to make sure we cover our butts. Not a lot of our suppliers do that for us.

D Rosenfeld

Thank you for assisting us with the lens and working under our strict deadline. The ability to get the lens so quickly was a huge help to us!

H Gilsenan

Senior Buyer

I can say with all sincerity

that the very best attention to detail from beginning to end, along with the

most personable service with a healthy touch of professionalism – has been

experienced through my dealings with Andre.

He stands out from all the other

inside sales and account manager specialists I have dealt with. He’s that good.

M Castellanos

Analyst

Maria Yrbas has been our Lore Account rep for quite some time now and we couldn’t be happier with the services she provides us. She takes the time and care into everything we ask of her.

She is thorough in everything she does and never misses any details. She goes above and beyond, especially with turnaround time for quotes…I am never left hanging. If she’s unavailable for some reason, she always lets us know who we can contact. She is our “go to” for all of our camera needs. I am truly happy she is our rep and for a while now, my friend. She is an asset!

Z. Zaidi

Working with you has been an absolute pleasure. Your dedication and commitment to ensuring that we received the right products for our project have been unmatched. You've always been responsive to our needs and have gone above and beyond to ensure that we were satisfied with your services.

I appreciate your willingness to help me with preparing quotes that were tailored to our specific needs, which made our purchasing process a breeze.

Your knowledge of the industry

and your ability to provide suggestions for the right products for our use case

have been invaluable. Your accurate lead times and timelines for products have allowed us to plan our project efficiently and effectively. Your assistance and support have helped our project progress and deliver the desired results as evidenced by our recent video.

P Sanchez

Project Coordinator

Maria Yrbas was extremely helpful in facilitating the account set up with Lore Technology and more importantly was able to work within our budget. Maria was attentive every step of the way and made it possible to meet the strict timeline with our client. We look forward to continuing working with Maria and Lore Technology.

M. Groth

Andre has been providing top notch service since we started working with your company a few months ago, he responds quickly to any email and if he doesn't have an immediate answer to my question, he keeps me in the loop as he is trying to figure it out. Andre always sends updates as lead times change and has made it very easy to continue to use your company as our lens and filter supplier. 5 stars for customer service and support.

I. Arce

Andre is a fantastic resource; he is proactive in informing me of the availability of Flir items if there is a need for them, and he gives prompt responses to inquiries, order confirmations, and tracking information. Thank you for the help, Andre, greatly appreciated!

.Bagnell

Senior Quantum Engineer

We have been extremely pleased with the services provided by Lore+/Wilco. As our primary point of contact, we have also been very pleased working with Maria Yrbas. We appreciate her responsiveness, attentiveness to detail, and assisting in the successful completion of our projects. Thank you to Maria and the whole Lore+/Wilco team for helping us to be successful.

K. Dehart

Purchasing Manager

Just wanted to reach out and say thank you Andre for the prompt response as well as the phone call to inform me.

It’s rare to find such great service nowadays. I really appreciate it!

R. Silva

I would like to thank you for all your service. You always kept me informed about every step of the purchase and always looked for the

best alternatives to serve me as quickly as possible. You and your team were always available and always quick to support and send information. Thank you for everything!

Pat H.

Mechanical Engineer

I can not speak high enough praise for Maria and the rest of her team! Her timely responses and punctuality allow our team to deliver the best research products for our customers. Maria is professional, knowledgeable, and does an excellent job at communication during the entire procurement process.

Andrew M.

Mechatronics Engineer

I have been working with Maria to buy imaging sensors and camera components. I am an engineer and I work with many different sales reps in designing our machine vision solution for agriculture. Maria has consistently been the most helpful and responsive sales rep that I have the pleasure of working with. She is able to get me the components I need on schedule. She also gives me detailed insight into the supply chain so that I can make purchasing decisions in advance.

V. Pessino

Ph.D

I appreciated all the help and efforts over these years from Maria

Yrbas, and I will absolutely keep her in mind for future work. Best

wishes~ Veronica

Steve C.

Chief Production Officer

Thank you Maria for staying after this and helping us coordinate with Basler. I wish every partner was as proactive, persistent and responsive as you’ve been! Greatly appreciated!

N Kulkarni

Dept of Materials Science

I highly appreciate the help that Maria has extended during procurement of Flir Camera and Tamron Lens. She clarified all our queries regarding performance and integration of the system.

Van Horn

Engineer

I would also like to thank you for the wonderful experience working with you! You have always had our best interest and helped so much in getting the system up and running.

E Hueners

Operations Manager

When faced with supply chain uncertainties, it is vital to have the Darlene and Lore Tech team on your side. Her prompt and knowledgeable responses have allowed us to navigate successfully through camera challenges that risked shutting down our production line. They have always worked with us to find the optimal solution to our lead time issues to keep our production running!

R Zakoor

Purchasing

I appreciate all your hard work. You always try to keep me informed and take extra steps to make sure we cover our butts. Not a lot of our suppliers do that for us.

D Rosenfeld

Thank you for assisting us with the lens and working under our strict deadline. The ability to get the lens so quickly was a huge help to us!

H Gilsenan

Senior Buyer

I can say with all sincerity

that the very best attention to detail from beginning to end, along with the

most personable service with a healthy touch of professionalism – has been

experienced through my dealings with Andre.

He stands out from all the other

inside sales and account manager specialists I have dealt with. He’s that good.

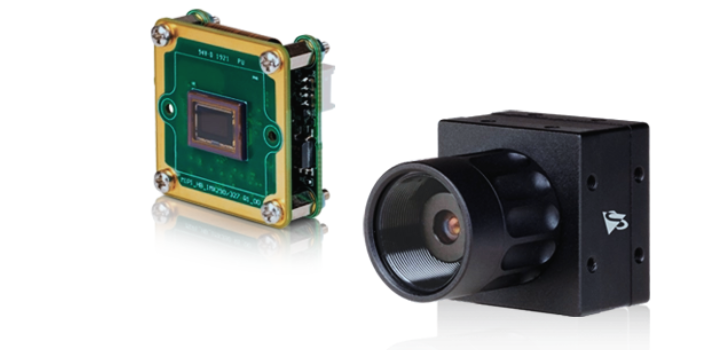

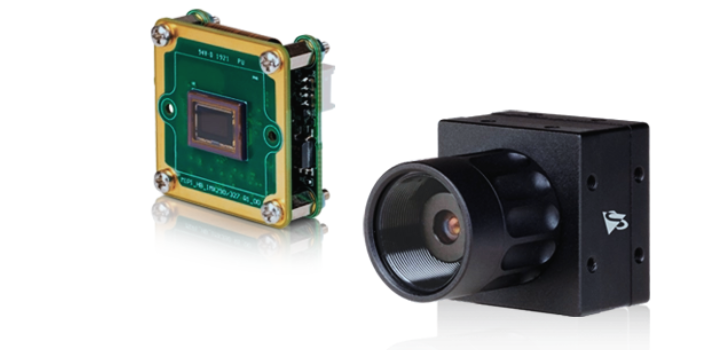

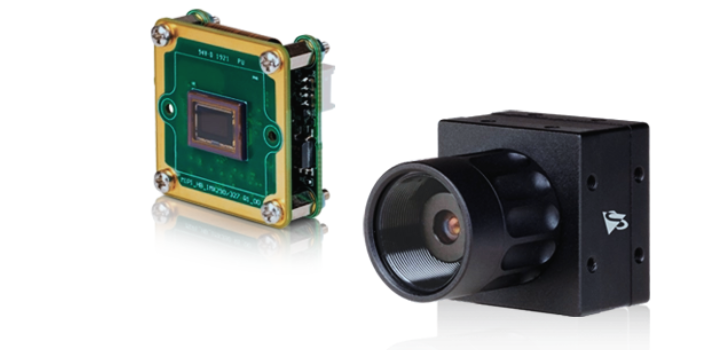

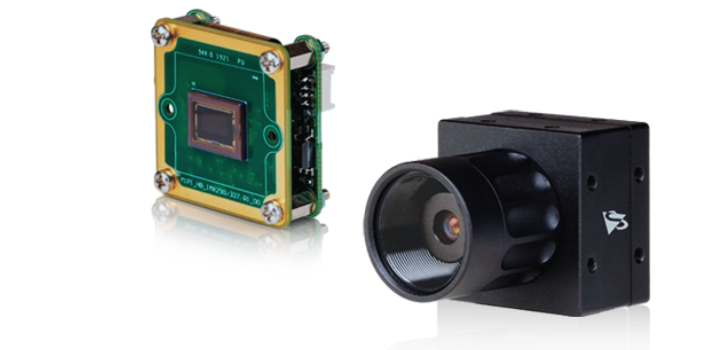

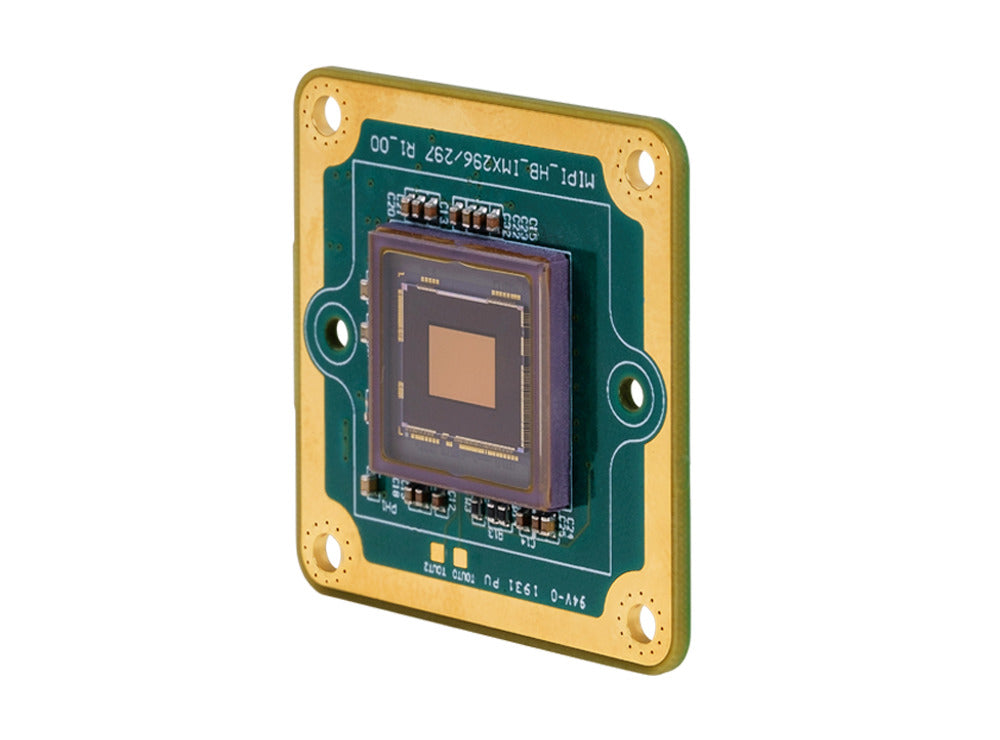

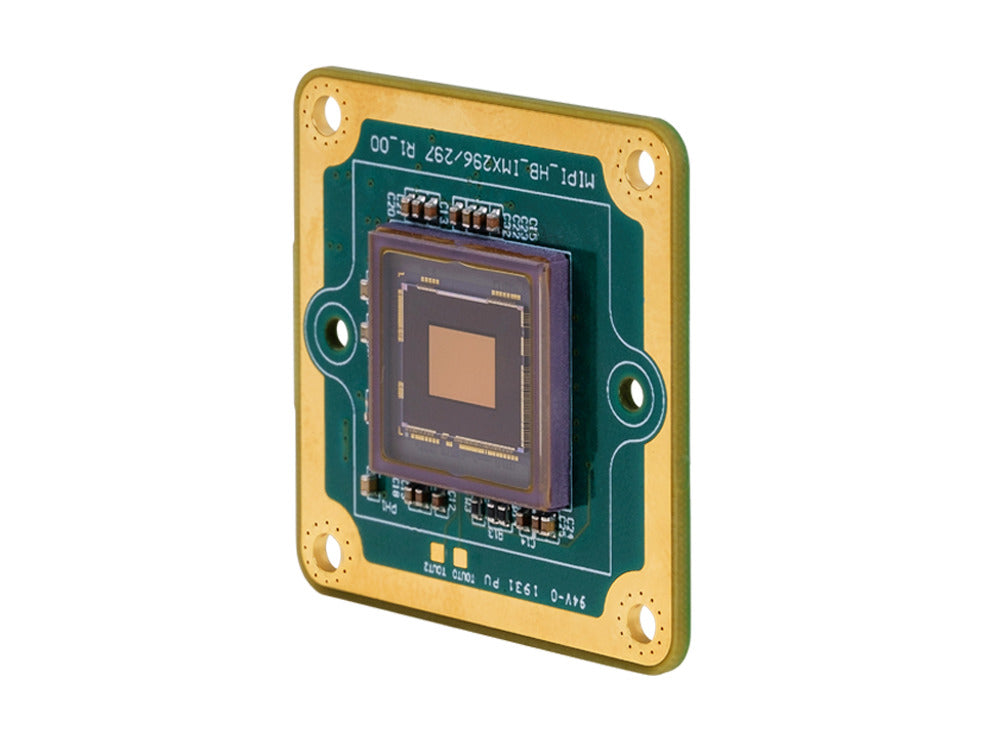

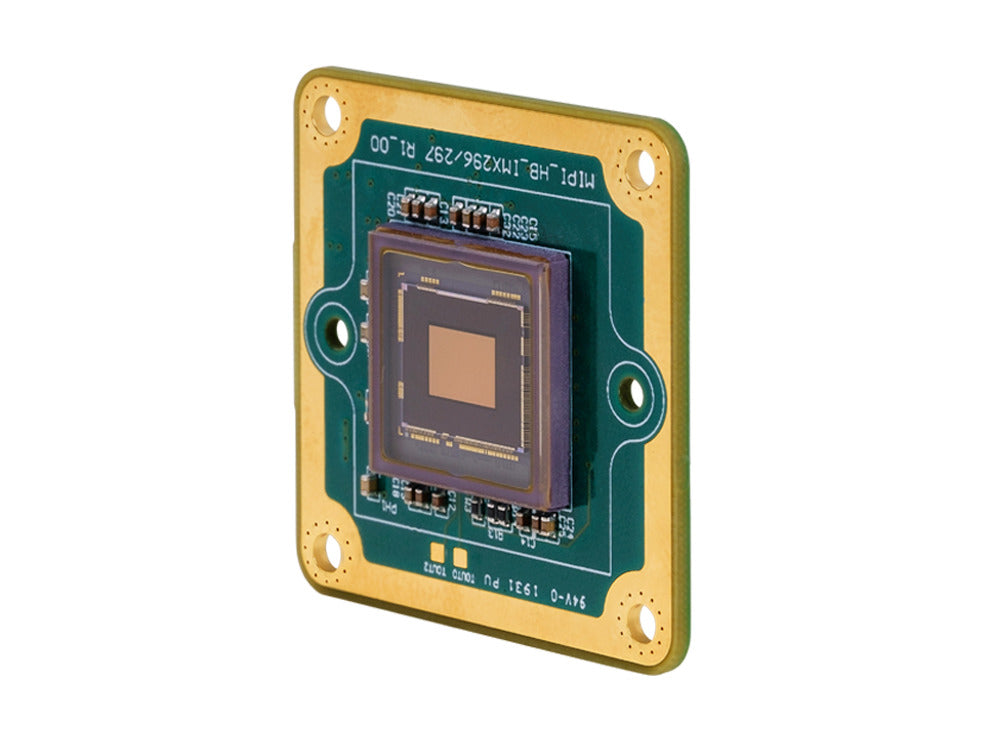

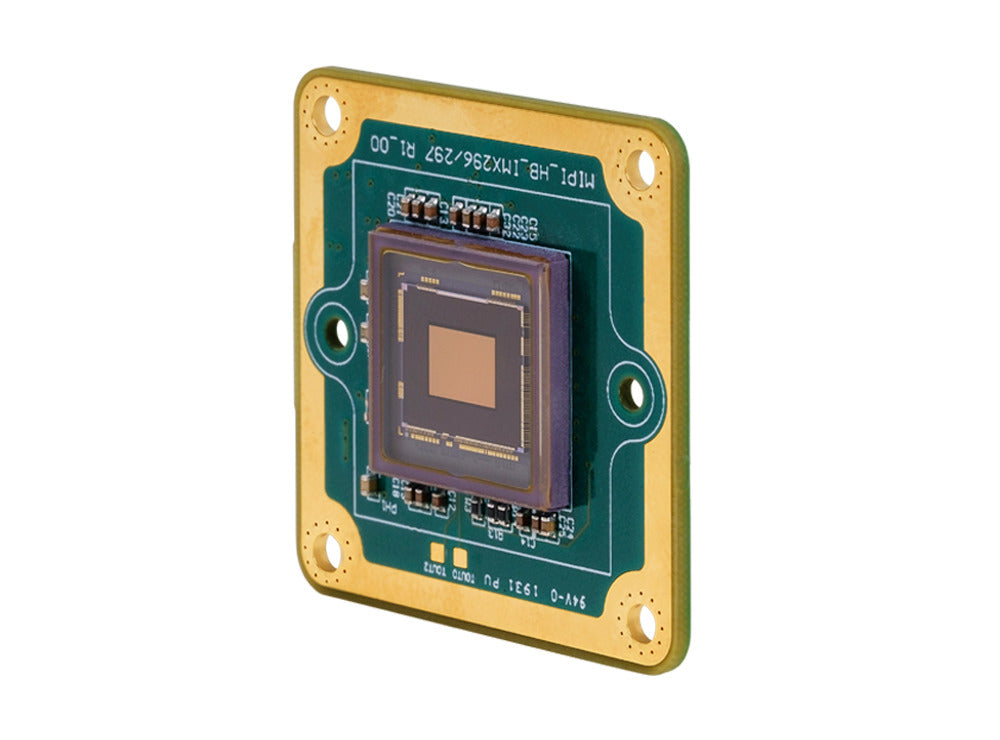

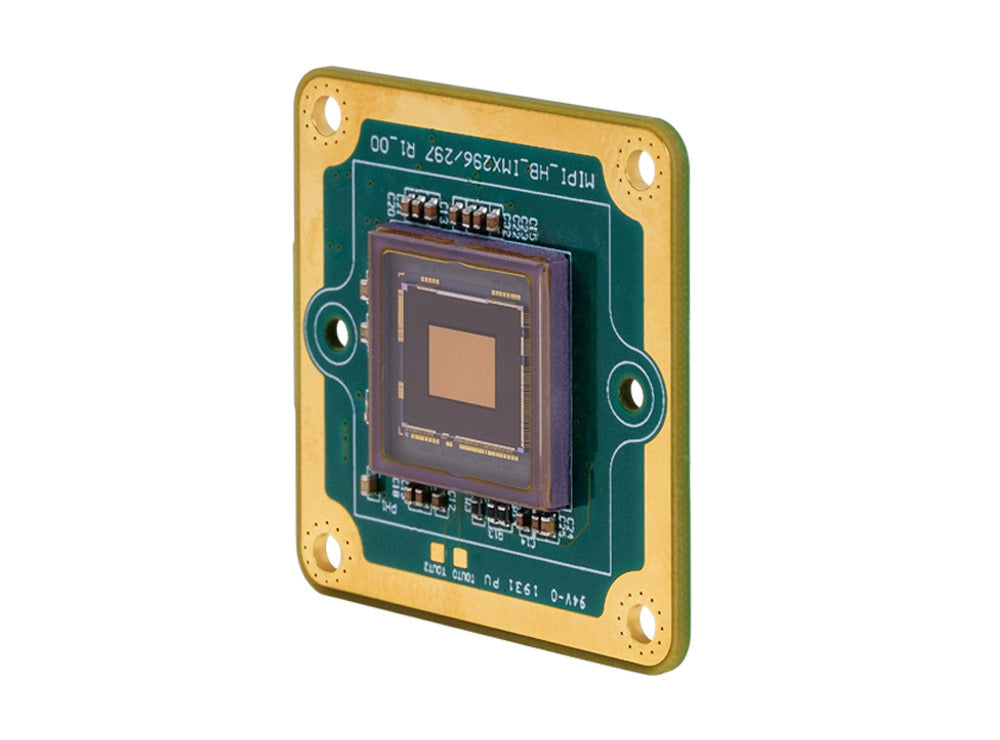

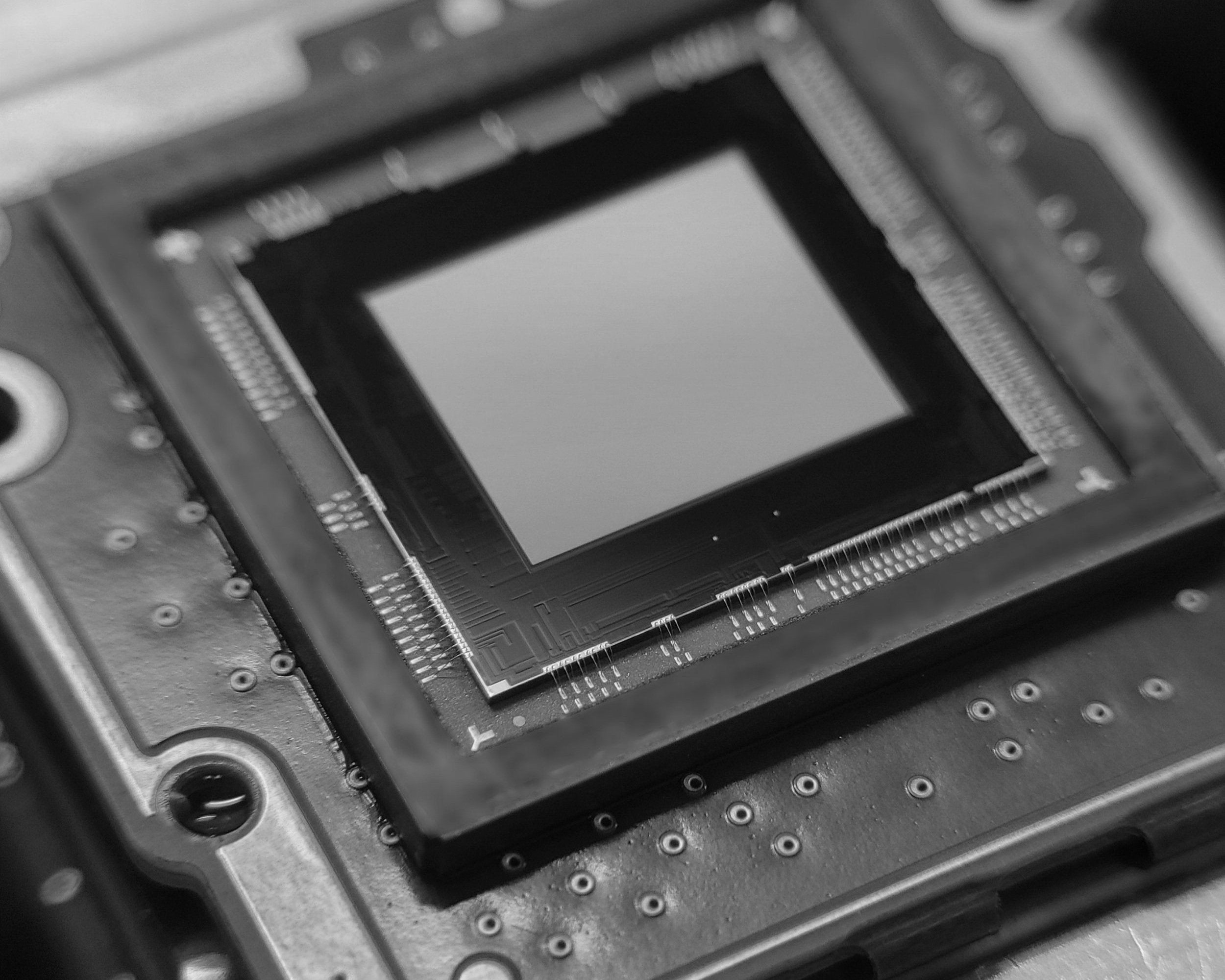

Product Spotlight

Deep Learning & AI Series Cameras. Browse below, or ask us for more details!

AVAILABLE CUSTOMIZATION

If you are looking for a custom solution, chances are, we can help! Just send us a general outline with your application details, and we’ll get started on the ideal solution for you!

BRING YOUR IMAGING APPLICATION TO LIFE WITH CUSTOMIZED PRODUCTS FROM Wilco Imaging

Subsidiary company, Wilco Imaging has been customizing imaging components since 2003, designing exceptional products, and delivering the very best in imaging technology.

Download a project sampler below or contact us for more information.

OUR PARTNERS

Read MoreLore Technology is proud of the valued partnerships we have created with industry innovators and leaders. We work with the absolute best in our field. Browse some of our vendors below or send us an inquiry for more information.

Crafting Technology & Expertise

We are a veteran, minority-owned, small business with a collective 40+ years of experience in the vision and electronics industry.

We pride ourselves on our ability to build partnerships based on our technical know-how and focus on service. We take great measures to stay up to date with relevant industry knowledge and product training and certification.

We provide complete vision system solutions for a wide range of industries, including machine vision, autonomous vision, robotic and industrial vision, medical and microscopy, security CCTV, military and government. Whether you are working on cutting edge machine vision technology or trying to maintain systems that rely on a mix of old and new technology, we stand ready to help your team design or find solutions.